Family-owned since 1985

We provide you one-stop manufacturing services including 3D printing, tooling, moulding, die casting and secondary processes.

TS6949:2016 & ISO 9001:2008 Certified

Comparing Pad Printing, Silk Screen Printing, Laser Printing and IML Technology on plastic parts

In modern manufacturing and product decoration, applying logos, labels, graphics, and information onto parts or packaging is critical for branding, compliance, and usability. Four common methods used for this purpose are pad printing, silk screen printing, laser printing, and in-mold labeling (IML). Each technique has unique strengths and ideal applications depending on factors like surface type, durability, resolution, and production volume.

Let’s explore how these printing methods work and how they compare.

1. Pad Printing: Great for Irregular Surfaces

Pad printing uses a silicone pad to transfer ink from an etched plate onto a product surface. It's especially useful for complex, curved, or textured surfaces.

How It Works:

An image is etched into a metal plate (cliché).

Ink is spread over the etched area and picked up by a soft silicone pad.

The pad presses onto the part, transferring the image.

Pros:

Excellent for 3D surfaces and fine details.

Works on a wide variety of materials.

Cost-effective for small to medium runs.

Common Uses:

Medical devices

Buttons, keypads

Toys and tools

Consumer electronics

2. Silk Screen Printing: Bold and Durable

Silk screen printing (or screen printing) involves forcing ink through a mesh screen onto the substrate. A stencil blocks off areas not to be printed.

How It Works:

A mesh screen is prepared with a stencil.

Ink is pressed through the open areas onto the product.

The ink is dried or cured to bond with the material.

Pros:

Vivid colors and strong coverage.

Very durable with proper curing.

Scalable for large batches.

Common Uses:

Bottles, containers

Apparel and textiles

Promotional products

Signage and panels

3. Laser Printing/Marking: Precision Without Ink

Laser printing (also called laser marking or engraving) uses a focused laser beam to etch, burn, or alter the surface of a material. It is a non-contact, ink-free method often used for permanent marks.

How It Works:

A high-energy laser beam is directed by software to trace a design.

The laser alters the surface by removing material or changing its appearance.

Pros:

High precision and detail.

Extremely durable—resistant to wear, chemicals, and heat.

Environmentally friendly (no ink or solvents).

Common Uses:

Metal parts and tools

Plastics and electronics

Serial numbers and barcodes

Branding on luxury goods

4. In-Mold Labeling (IML): Labels That Last

In-mold labeling is a process where a pre-printed label is placed inside a mold and becomes fused with the product during molding.

How It Works:

A printed label is inserted into the mold.

Plastic is injected or blown into the mold.

The label and product become a single, seamless item.

Pros:

Extremely durable—part of the product.

Scratch-, water-, and chemical-resistant.

No need for post-production labeling.

Common Uses:

Food and beverage containers

Cosmetic packaging

Household goods

Automotive parts

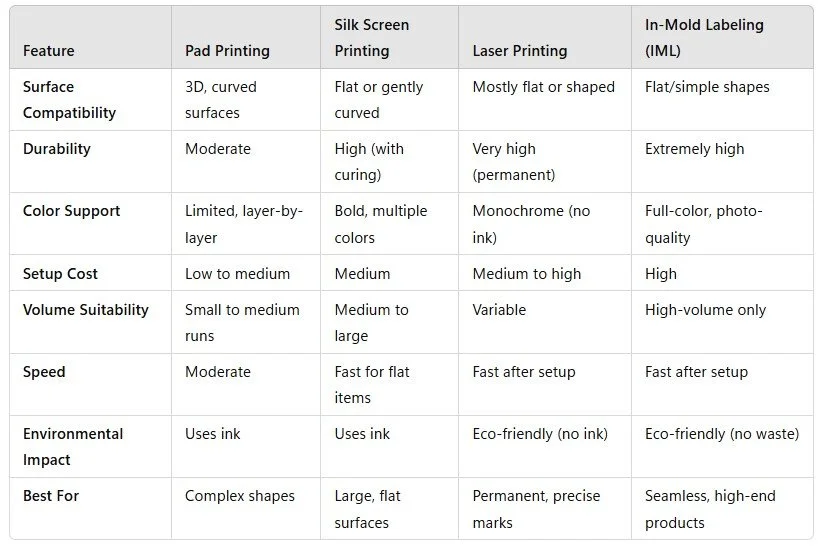

Comparison Table

Conclusion: Which Method Should You Choose?

Pad Printing is ideal for small logos and text on curved or irregular parts, like buttons or caps.

Silk Screen Printing works best when you need bold, colorful graphics on flat surfaces in medium to large volumes.

Laser Printing is perfect for permanent identification, serial numbers, and sleek branding with high precision.

In-Mold Labeling is the best choice for premium, long-lasting labeling fused into plastic items during production.

The right technique depends on your product’s shape, material, intended use, aesthetic goals, and budget. In many manufacturing operations, multiple methods are used in combination to achieve the perfect result.