Family-owned since 1985

We provide you one-stop manufacturing services including 3D printing, tooling, moulding, die casting and secondary processes.

TS6949:2016 & ISO 9001:2008 Certified

Tooling

We have 20+ years of experience designing and building Class 101 & 102 injection molds for North America clients.

Our expertise includes:

Precision Molds

Stack Molds

MUD Molds

High-Gloss Molds

2K Molds

SLR Molds

Rubber Molds

Mold design

A good design will make molds easy to operate and maintain, efficient, last long and meet all specifications at lowest possible cost. First, we provide DFM (Design for Manufacturability) and Mold Flow Analysis. This will foresee all potential issues, with our recommendations on solutions. Also, locations and types of gates, parting lines, ejectors will be addressed. Steel will be recommended with desired hardness. Target cycle time will be estimated. Once DFM is approved by clients, we proceed on mold drawings. 3D mold drawings are available at the format of IGES, STP, DXF etc. Mold drawings with BOM will be provided to clients for approval before mold building.

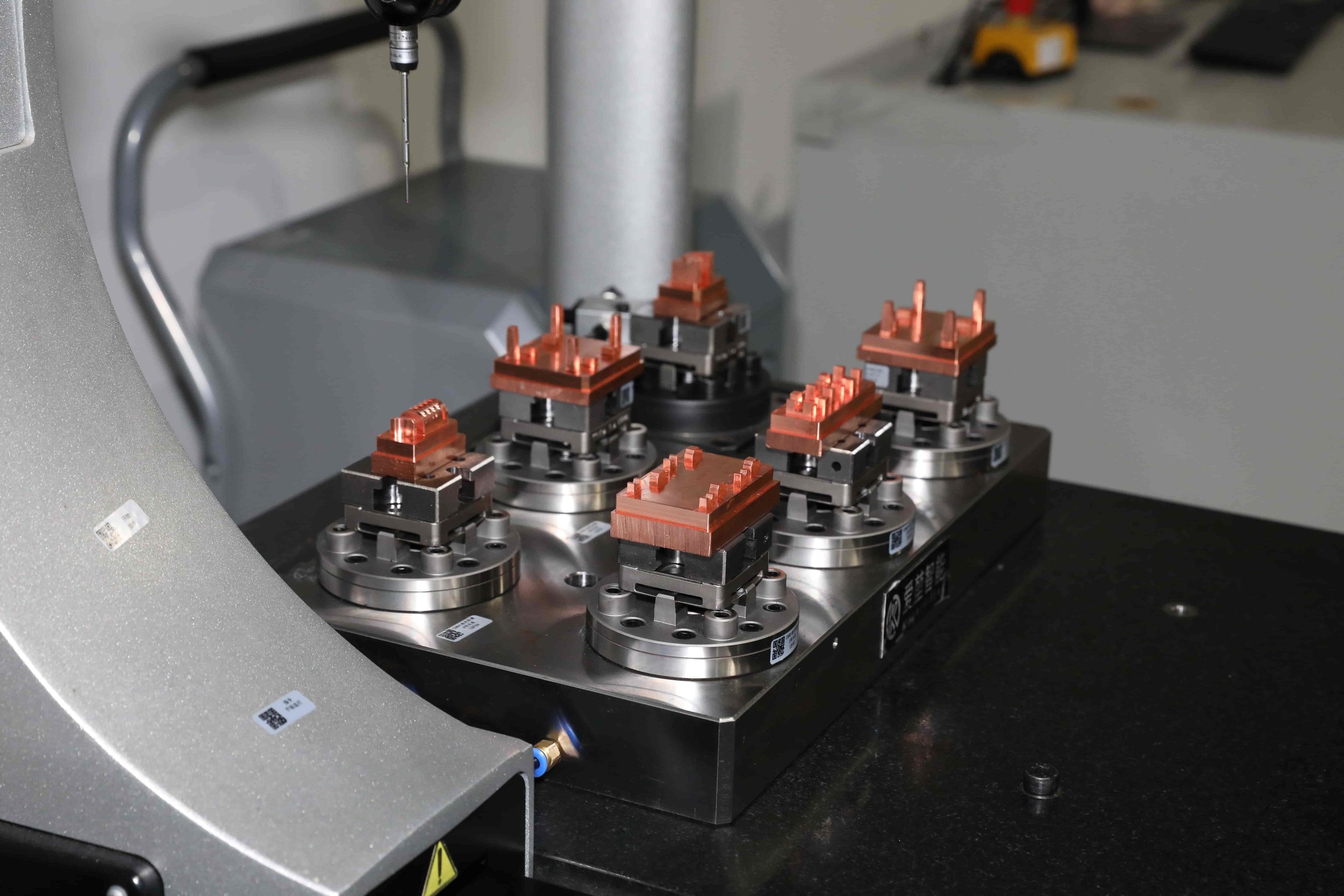

Mold building

Our molds are machined with advanced precision CNC, EDM and slow wire cutting machines etc. that are imported from Japan and Germany. Dimensions can be acurate upto 0.02mm-0.03mm. QR code is used for each mold component for actual progress follow up. Our skilled bench workers do final fine touch to make the molds flawless. 98% of our new products are approved at T1 without further modifications.

Tryout

For T1, we provide report including the information below to our clients.

Full dimension inspection report for each cavity

Video of one injection cycle

Injection parameter settings

T1 sample analysis

PPAP

For molds that are remained in our plant for production, we offer PPAP (Production Parts Approval Process) if needed.

Mold Inspection before delivery

For molds to be exported overseas, we conduct a final inspection based on a detailed checklist. Clients receive a recorded inspection report for review and approval before shipment.

Along with the mold, we provide a complete documentation package that includes:

Final part drawing

2D & 3D mold drawings

T-end sample inspection report

Molding parameter setting card

Mold inspection checklist report

Steel certification

Hardness certification

Heat treatment certification

Spare parts list

Other relevant documentation as needed

3D printed conformal cooling channels are applied for better cooling.

MFA